Zhongshan yanben Coating Technology Co., Ltd

Contact person: Mr. Wang

Mobile: 13427001396

Tel: 0760-88500365

Fax: 0760-88500325

Q Q :2209471440

Email: 2209471440@qq.com

website: www.gdzsyanben.com

Address: Dongrui Industrial Zone, Dongsheng Town, Zhongshan City, Guangdong Province

1. Related industries

Electrostatic powder spraying is widely used because of its easy automatic production, good surface quality, economic and environmental protection. It has covered almost all the fields requiring surface treatment and can be seen everywhere in our daily life.

As the main body of electrostatic spraying, spray room and recycling system have been paid more and more attention by users. How to improve the spraying quality? How to reduce powder consumption? How to improve production efficiency? How to reduce the color change time? How to improve the working environment? How to reduce labor costs and many other issues are closely related to the spray room and recycling system, which plays an important role in the whole painting line.

2. Relationship between spray room and recovery system and powder

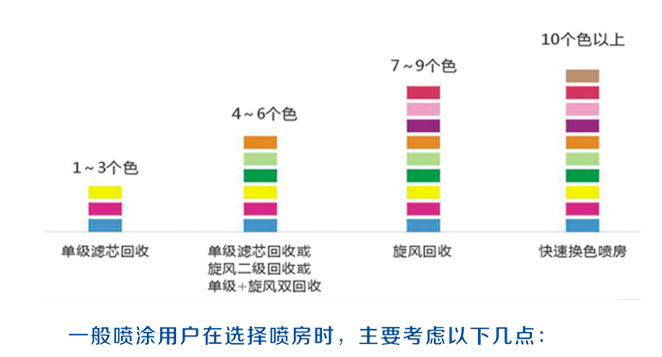

The selection of spray room and recovery system is related to many factors, such as powder color, powder type, workpiece shape, installation site, spraying requirements, etc. The spray room itself has many types, from the recycling system, there are filter single-stage recycling spray room, small cyclone two-stage recycling spray room, large cyclone two-stage recycling spray room, etc.; from the material of spray room, it can be divided into stainless steel plate spray room, plastic spraying steel plate spray room, engineering plastic spray room, sandwich spray room, etc.; from the sprayed workpiece, it can be divided into ordinary Hardware spray room and aluminum profile spray room From the point of powder spraying, it can be divided into ordinary organic powder spraying system and enamel powder spraying system

Large / small cyclone powder room_ Electrostatic spraying equipment_ Zhongshan yanben Coating Technology Co., Ltd. powder is the largest consumption material of electrostatic powder spraying line, which accounts for more than 70% of the cost of consumable materials of electrostatic powder spraying line. The quality of spraying room and recycling system is related to the consumption of powder per unit area. Therefore, the selection of a suitable spray room system is closely related to the core competitiveness of customers.

In addition to the commonly used powder, many similar powder, metal powder, enamel powder, glossing powder, etc. have some special requirements for the spray room. Only a suitable system can guarantee the spray quality of customers and the maximum utilization rate of powder. Examples are as follows:

For micro powder spraying (now it is generally considered that the average particle size below 20um is defined as micro powder), the most economical way is to use single-stage recovery of filter element with high capture efficiency, which can save powder to the maximum extent. If large cyclone or small cyclone recovery is adopted, some special designs are needed, which can reduce the amount of waste powder in the secondary recovery system.

For general metal powder, it is easy to produce color difference when the powder is recycled. Therefore, the recycling path should be shortened as far as possible, and the recycled powder and new powder should be evenly proportioned.

For glossing powder, because of its high resin content and easy oxidation, it is not suitable to pass through high-speed recovery pipeline. At the same time, in order to ensure the quality of spraying, the recovery of glossing powder should be filtered by a powder sieve of more than 180 mesh.

3. Relationship between spray chamber and electrostatic spray gun

Relationship between spray chamber and electrostatic spray gun

The spray room is the space for spray operation; the spray gun affects the powder loading rate, surface quality, and the permeability of the edges and corners of the sprayed workpiece, while the spray room determines the recovery effect, powder reuse rate, quality of the recovered powder, cleaning and color changing time, and spraying working environment; For the cyclone recovery system, the recovery and reuse rate of powder has a great relationship with the powder loading rate of spray gun. See the following table for details:

4. Relationship between spray room and compressed air

Compressed air is indispensable in the cleaning process of the recovery system of the spray room. With the improvement of the automation level of the equipment, the use of compressed air is also increasing, such as automatic powder recovery, cleaning when the spray room changes color, instant cleaning and recovery of the powder at the bottom of the spray room, cleaning of the filter element, automatic cleaning of the powder supply pipe of the spray gun in the powder supply center, etc The efficiency of the equipment is further improved by adding the function, but at the same time, many bad problems of spraying products are also directly related to the compressed air, such as shrinkage cavity, bubbles, recycled powder agglomeration, etc., which are greatly related to the water content or oil exceeding the standard in the compressed air. Therefore, the quality of compressed air in powder spraying system is very important. There are many ways to ensure the stability of compressed air quality, such as using adsorption dryer and adding high-precision air filter, and the cost is not very much!

5. Relationship between spray room, isolation room and surrounding environment

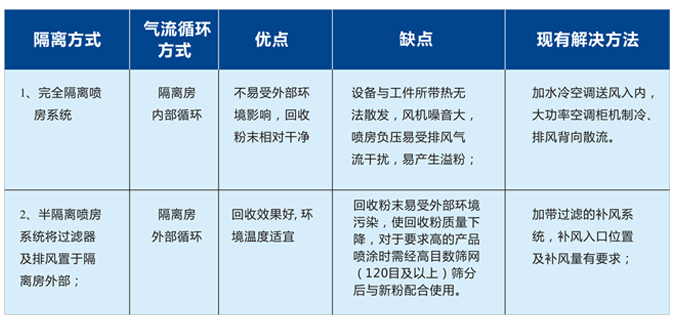

For customers with a spacious environment, good site management (such as floor paint), no dust pollution, no strong wind interference, no high temperature radiation, techuang technology believes that it would be better not to build isolation room. But only a few customers have the above conditions, most of them will choose to build an isolation room to isolate the spray room, so as to avoid the external environment pollution to the powder and the interference to the recovery system. The customer's choice of isolation mode in the construction of isolation room:

The first method mentioned above is used by many customers. This method has relatively high requirements for equipment configuration and structural design. After many customers use some immature equipment in this way, there are some problems such as serious powder overflow and internal heat tightness in the isolation room, which lead to the operators unable to enter the enterprise;

Relatively speaking, the second method is more and more recognized by some new and old customers. This method has relatively low requirements for equipment configuration and structural design, affordable price, durable, relatively low use cost, and good effect.

However, when spraying the products with high quality requirements, the recycled powder will inevitably be contaminated by dust, sand, fiber and so on. At this time, the powder screening machine with 120 mesh or more screen should be equipped to screen and mix with the new powder to avoid quality problems;

The third way is also a closed-circuit external circulation system which is being designed by the mechanical and Electrical Technology Department of Dechuang. This way will solve the shortcomings of the above two ways, but the cost of the whole set of equipment is relatively increased!

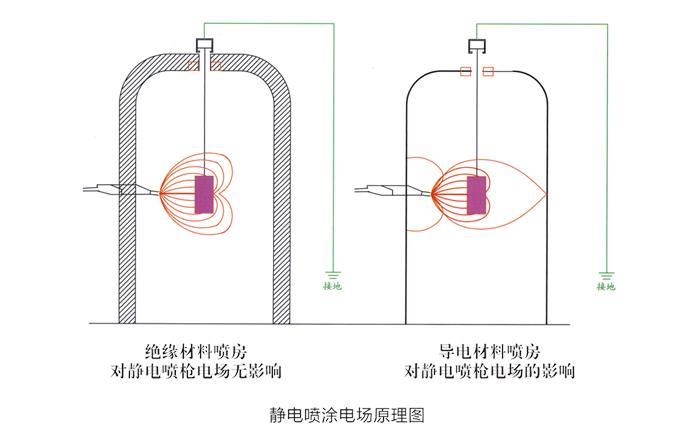

6. The relationship between the material of spray room, spray gun and powder loading rate of workpiece

Note: on the left side of the figure above is the spray room made of sandwich structure anti conductive engineering plastic, and the 120mm thick insulation has no effect on the electric field of the electrostatic spray gun, so that the ejected charged powder particles are absorbed on the surface of the workpiece under the action of the electric field; on the right side of the figure above is the spray room made of metal conductive materials (such as spray plastic sheet, galvanized sheet, stainless steel sheet), which has no effect on the electrostatic spray The electric field of the spray gun has a great influence, because at this time, the spray room is quite large, and if the large workpiece will also absorb the charged powder particles, so we usually find that there is a thick layer of powder on the inner wall of the metal spray room, and it is not easy to clean.

It can be seen from the above that the spray booth made of sandwich structure engineering plastics will bring the following benefits:

Improve the powder loading rate of the workpiece and save the powder.

It can also protect the electrostatic spray gun, because there is no need to use large powder output and high electric field to make up for the consumption of metal spray room, so a good gun should be equipped with sandwich plastic spray room.

Because the inner wall of the plastic spray room is not easy to stick powder, the time of color changing and cleaning is fast, the production time is increased, and the production capacity is improved. Spraying line in the process of color change is non-stop drying furnace, curing furnace, so the shorter the color change time, the more energy saving, but also reduce the time of workers and other products out of the furnace, also reduce the cost, improve the efficiency!

Copyright: Zhongshan yanben Coating Technology Co., Ltd

Address: Dongrui Industrial Zone, Dongsheng Town, Zhongshan City, Guangdong Province Tel: 0760-88500365